Solar energy is by far the fastest growing form of renewable energy and that’s down to the boom in the installation of home systems.

Utility and commercial systems have had a slower take up due to planning permission, NIMBYs and the lack of political will.

This is changing though, as new tech and different ways of capturing the sun’s rays start to become more commercially viable.

One of the latest and most exciting innovations in the industry is the development of Thin Film Solar Panels.

What are Thin Film Solar Panels?

Much as their name suggests, they are just like standard solar panels but much thinner.

That said, if it was that simple we wouldn’t need a blog explaining the ins and outs of this emerging technology.

The basic science behind a Thin Film Solar Panel is the same as any other PV panel.

The light rays hit the PV cells and ‘jiggle’ the molecules inside, converting the light energy into electrical energy.

The big difference is just how thick those PV cells are.

Basically, a standard solar panel is made up of silicon cells that are around 200 and 500µm (Micrometres) thick.

The optimal thickness is around 100µm, but this makes handling them difficult, so they are made thicker for practical reasons, such as how they are made and how easy they are to handle.

Layers in a Thin Film Solar Panel are somewhere between 300 to 350 times thinner than standard panels – making them easier to manipulate, bend and shape.

They also differ from their monocrystalline and polycrystalline cousins because they use different materials within the cell.

What are Thin Film Solar Panels made of?

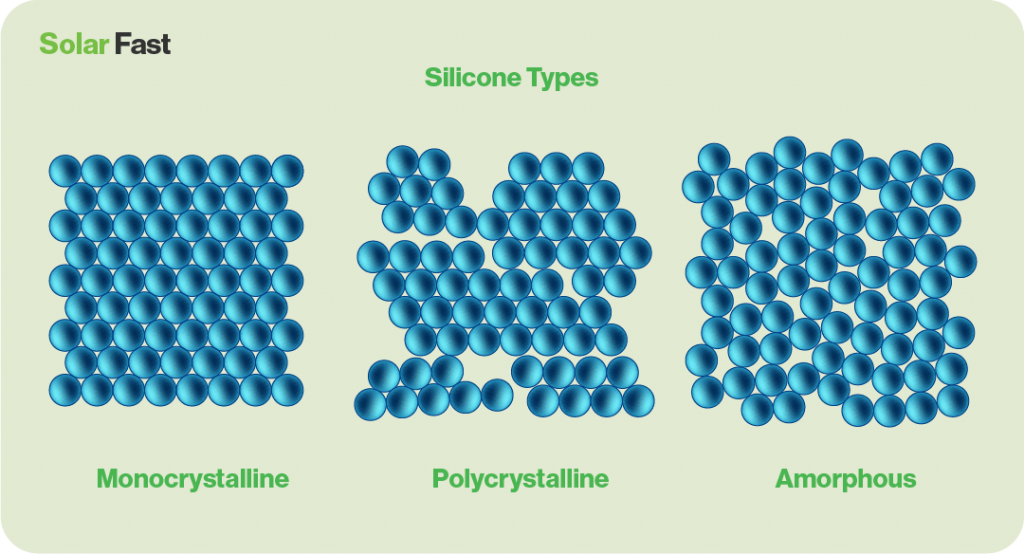

Traditional solar panels use PV cells made from crystallised silicon.

In monocrystalline panels, those cells are made from a single crystal, which makes them expensive but much more efficient.

Whereas, polycrystalline panels use cells that are made from many crystals fused together, which is a much cheaper manufacturing process proves but reduces the efficiency.

Crystalline silicon is usually denoted as c-Si.

Thin film solar panels can use a few different materials, including non-crystalline, amorphous silicon which is denoted a-Si.

They can also be made from Cadmium telluride, Copper indium gallium selenide and even organic PV cells.

Amorphous silicon

Within Crystalline silicon the molecules are arranged to create either one, very uniform crystal (mono) or lots of irregular crystals all jumbled up (poly).

In amorphous silicon the molecules are all over the place, having no real order or shape.

This makes the silicon easier to work with.

Cadmium Telluride

This is a compound made by mixing Cadmium and Tellurium.

Cadmium is a very common element found in everything from rocks and soil to chocolate and hamburgers.

It is also very toxic in high amounts.

Conversely, Tellurium is an incredibly rare element on Earth – but there are tons of it outside the Earth’s atmosphere.

It is silver/white and is used to vulcanise rubber, tint glass and as a catalyst in oil refining.

Combining these 2 elements creates a fantastic semi-conductor.

Copper Indium Gallium

This semi-conductor is made by mixing 3 metals together – Copper, Indium and Gallium.

These elements are fairly good conductors on their own, but when mixed they create a PV cell with an efficiency of over 20%.

Organic PV

It is solar made from plastics! Well, polymers.

The material used in Organic PV cells works in the same way that traditional semiconductors do, but the efficiency is currently sitting at around 10%.

There are experimental organic PV cells that have touched 19.3% but these are not commercially available.

Organic solar will help us move towards clear PV and PV paint.

How are thin film solar panels made?

So, now you know what they are made of, here’s a quick breakdown of how they are made.

There are 3 layers in each panel.

A layer of Photovoltaic Material that can be made of various different materials – including those mentioned before. This generates electricity.

Then a Conductive Sheet is needed. This is a layer of conductive material that will move the electricity where it’s supposed to be.

You need to protect all that, so a layer of thin glass or plastic is added to keep everything inside safe from the elements.

How do thin film solar panels work?

In much the same way that traditional PV solar panels work – by using elements and semiconductors to convert the light into electricity.

The difference between thin film and traditional solar is that thin film doesn’t rely on cells made of crystals, but thin layers of PV material laid on top of one another.

The light hits these and ‘jiggles’ the molecules inside, this creates a ‘potential difference’ and the electricity is conducted along the wires across the panel.

Cost of thin-film solar panels?

The cost of thin film solar isn’t as high as one would think – but it is way less efficient than traditional panels also the area you have to cover would be larger.

That said, you can wrap it around stuff, lay it around corners, slap it on the wall … basically, it’s much more adaptable than other PV technology.

Let’s take a look at the average price of thin film solar.

| Generation | Thin Film Panel Cost |

| 3 kW | £3,120 |

| 4 kW | £4,160 |

| 5kW | £5,200 |

| 6kW | £6,240 |

Costs are pretty similar, the problem you have is the space needed for your panels.

4 kW of traditional solar panels would cover a space of 28 square metres, whereas the same output for thin-film solar panels would take up 42 m².

Advantages and disadvantages of thin film solar panels

This section is very much based on what’s available at the time of writing this blog but these things change fast, and we think Thin Film Solar Panels will become much more ‘the norm’ as the years go by.

Current technology means Thin Film Solar Panels are much less efficient than traditional panels and, because of the nature of their construction, they are more like to fail in just over 10 years – ‘normal’ PV panels will last 25 years or more.

Pay back time may be quicker on Thin Film Panels and, as they get more popular, the price will drop.

The biggest advantage of the Thin Film Panels is they can be fitted just about anywhere – on roofs, on walls, the top of vehicles, outside a tent, round corners and over any surface that gets some sun!

| Pros | Cons |

| Uses less semiconductor material so lower carbon footprint | Some have cadmium, which is carcinogenic, so don’t smoke them |

| Easy, and therefore cheaper, to install | More or less half as efficient as conventional panels |

| Great for caravans, campers, camping | Take up way more room |

| Lightweight | Not as easy to find |

| May be quicker to pay back | Only last 10 – 20 years |

So, what do you buy for your solar system?

This question really depends on what solar system, where it is and what it is being used for.

This table gives a little insight into what each panel type is good at – and where they are less attractive.

| Panel Type | Efficiency | Expense | Temperature Performance | Place usually used | Pros | Cons |

| Polycrystalline | 15 – 17% | Mid-range | Loses efficiency at higher temperatures | Domestic installation with lots of space, solar farms | Low cost | Lower productivity |

| Monocrystalline | 20 – 24% | Highest | Efficient at higher temperatures | Domestic installations with limited space | Very efficient | Highest cost |

| Thin Film | 10 – 20% | Lowest | Efficient at higher temperatures | Anywhere! Commercial, domestic, leisure uses all possible | Low cost, flexible | Lowest efficiency |